Apprenticeship

Thinking about your future

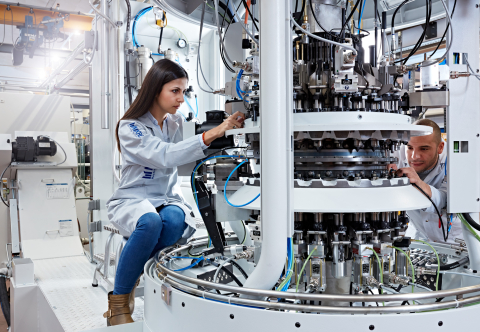

Our culture is embodied in our apprenticeship program. Mikron is dedicated to training and developing the next generation of technical experts. Our apprentices regularly have access to state of the art equipment, master craftsman and world class instruction. Graduates often rank in the top of their apprenticeship classes.