Machining solutions for the consumer goods industry

Are you searching for machining solutions that can help you optimize your production process and enhance your product quality in the highly competitive consumer goods industry?

Look no further than Mikron.

Mikron’s advanced machining systems for consumer goods manufacturers are designed to tackle the various challenges in the industry:

- Dealing with a wide range of materials, shapes, and sizes in consumer goods manufacturing

- Balancing the need for speed and efficiency with the need for precision and quality

- Meeting the specific design and aesthetic requirements of consumer goods

- Managing the challenges of high-volume production of consumer goods

- Incorporating new materials and technologies to improve consumer goods performance and functionality.

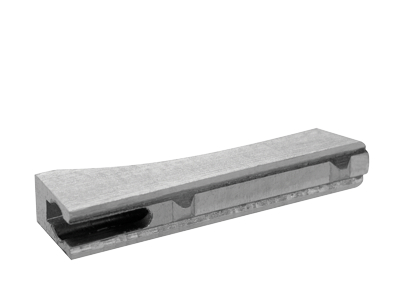

Our transfer solutions offer high output rates of up to 22,000 pieces/hour with optimal process efficiency, achieved through 6 to 24 stations depending on your manufacturing needs. Additionally, these systems are equipped with precise deburring capabilities that minimize the risk of damage or malfunction to your workpieces.

Moreover, our machining solutions are capable of machining entire parts in a single operating cycle, which increases efficiency and helps you reach your production goals faster.

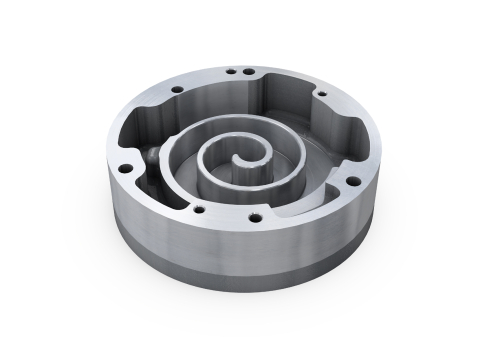

Specialized Solutions for the Consumer Goods Industry

Mikron offers specialized solutions for various areas. Our expertise and technology can support your manufacturing needs in the watch industry, eyewear, bike, and refrigerators sectors.

Learn more about our capabilities and how we can assist your business in the consumer goods industry.