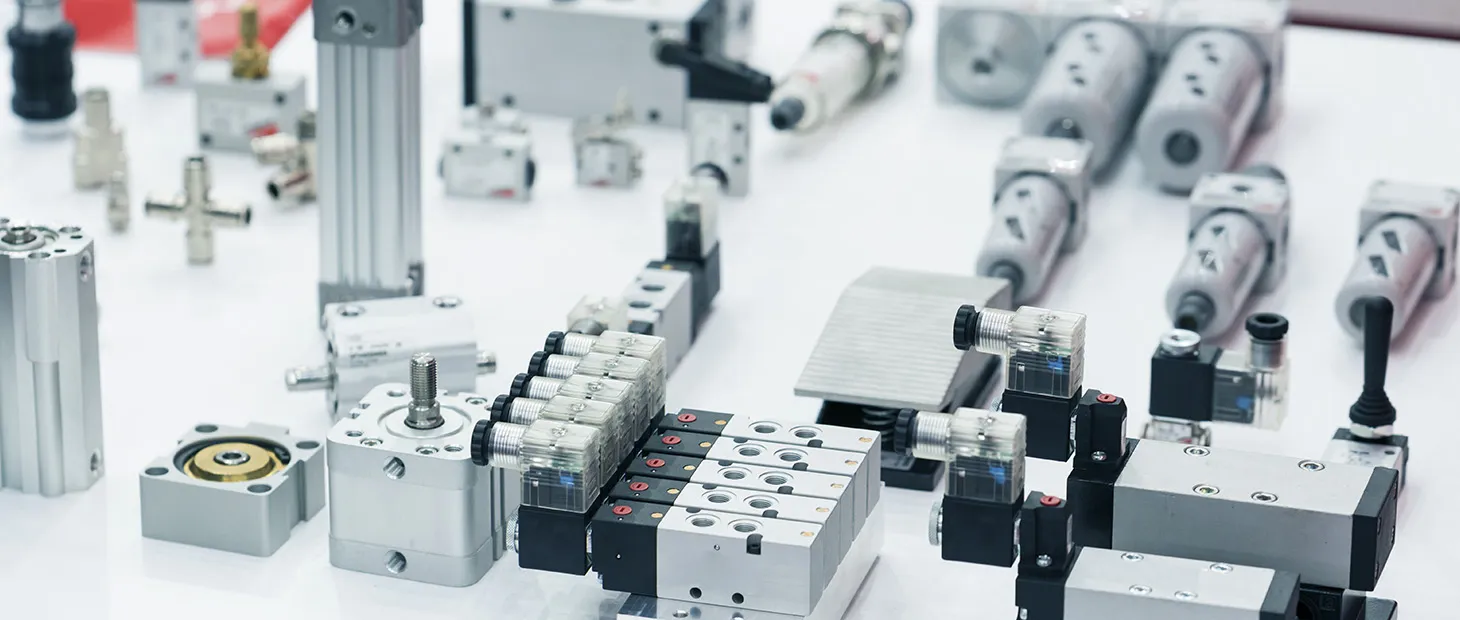

Hydraulic & Pneumatic Machining

Your machines must be everything: economical, fast(er) and precise. Our high performance machining systems support the production of quality hydraulic and pneumatic components. These machining systems perform operations such as drilling, milling, turning, grooving, threading and deburring, all on the same part, flexibly to produce different components at maximum capacity.