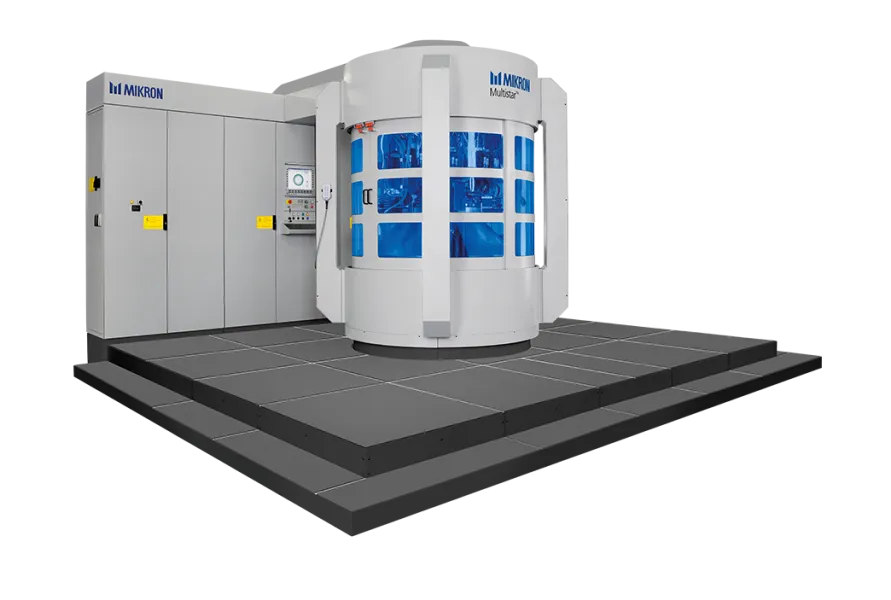

Key benefits of the Mikron Multistar NX-24

Productivity for high volume CNC machining

- Up to 30 parts per minute

- 24 CNC workstations with up to 44 machining units working simultaneously

- Fast-indexing rotary table for minimal idle time

- Simultaneous machining from multiple angles: top, bottom, side, or inclined

Full CNC flexibility & easy changeover

- 100% programmable and 100% versatile machining axes

- All axes are electronically controlled for quick changeover

- Various machining operations such as:

- Drilling, reaming, tapping, threading

- Milling with up to 4 axis interpolation

- Turning, grooving, recessing

- Deep hole drilling and 3D deburring

- Others e.g. measuring, washing, assembly

Precision CNC machining at its best

- Rigid, compact and thermally stable design

- ±2.5µm table position repeatability

- High precision clamping collets

- High tech Mikron spindles

- In process gauging; tool and clamping compensation

- Automatic out of tolerance part separation

Very cost efficient