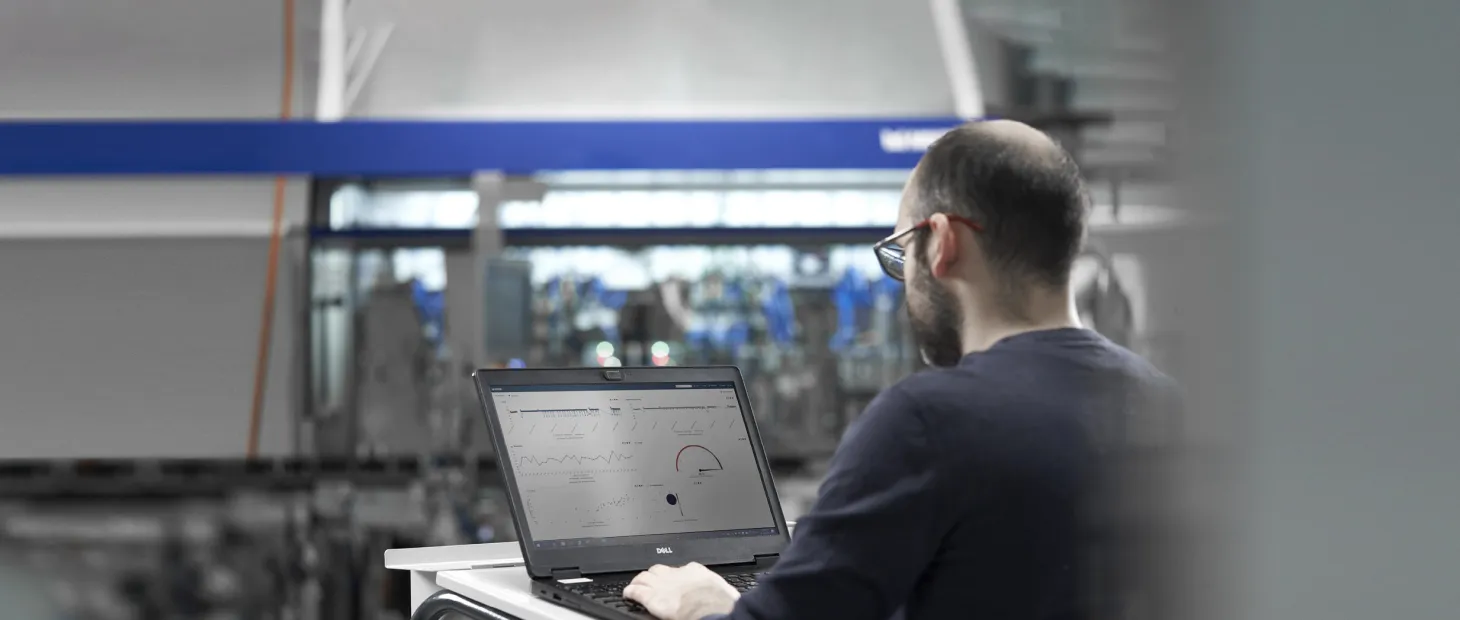

Data monitoring and full analysis always and everywhere available

Our digital solutions identify work processes that cause unnecessary costs within the automation process. With their help you better understand your equipment’s performance to increase the running time and productivity of your assembly line.