Typical parts and industries

The machining range of the Multistep XT-200 transfer system is very broad: It extends from simple drilling operations to complex milling operations. This makes it suitable for industries such as automotive, pneumatic and hydraulic, medical, watch and electrical; all of which require the production of complex, high-precision machined parts.

Mikron Multistep XT-200

Outstanding flexibility, cost effective and high CNC precision

The Mikron Multistep XT-200 is a next-generation precision CNC machining center, designed to deliver maximum productivity and flexibility for manufacturers requiring high precision machining parts.

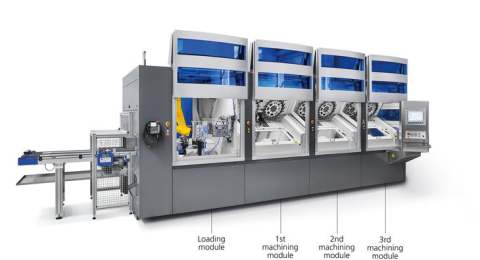

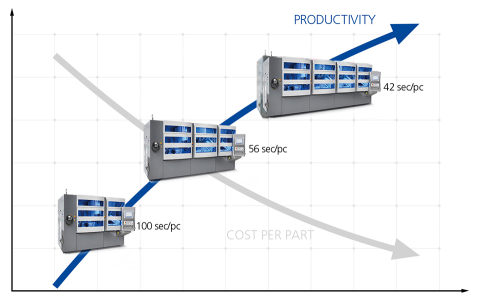

Thanks to its modular concept, the Multistep XT-200 offers a scalable and future-ready solution for both prototyping and large-scale production of precision machining parts. With up to 4 independently operating spindles and support for up to 144 tools, this system ensures exceptional precision CNC machining capabilities, even for the most complex components. An optional high-frequency spindle is available for high-speed machining.

The Multistep XT-200 can be expanded with additional machining modules (1 up to 4) to meet future production increases without compromising CNC precision (no need to add an additional loading/unloading module).

No matter how different the jobs are and no matter how large the batch size, the patented modular concept of the modular machining center allows you to switch easily and effectively between demanding machining operations and short runs.

Key Features

- Fully modular CNC machining center with 1-4 machining modules for workpiece dimensions of up to 200 x 200 x 200mm

- High precision machining parts production in both prototyping and mass production

- Full 5-axis precision CNC machining with interpolation and controlled cross-hole deburring

- Highest flexibility – Change-over within 10 minutes

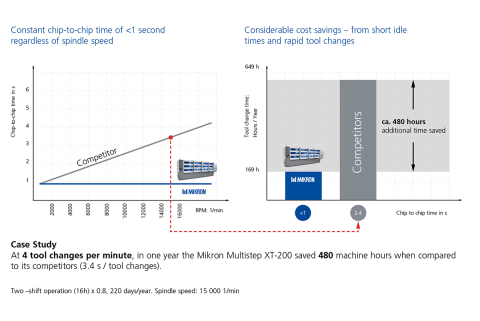

- Chip-to-chip time 0.9 seconds at a maximum spindle speed - saving up to 2000 hours per year

- Automatic part rotation for 6 side machining

- Automatic measuring of blank part and in-process with automatic compensation for optimal precision CNC machining

- Optional deburring, brushing, marking in the loading system

- SPC drawer and poke-yoke extraction

- Single completely integrated system for production, saving floor space and manpower

- Same machine model for very different applications, including high precision machining part production like ABS valve bodies or injectors

- Automatic loading from pallets or belt conveyor or manual

- Highest accuracy through 1 single process (comparing to multiple spindle process where you get different qualities coming from each spindle/clamping/tool) 1 gauss curve

CNC precision loading and unloading module

One for All

The material flow of blanks and finished precision machining parts can be optimally managed: Either by manual loading or by a 100% NC-controlled loading arm.

This system integration eliminates the interfaces that are prone to failure, as is often the case with conventional machining centers.

The NC-controlled loading arm can perform parallel tasks such as fully automatic repositioning of workpieces for 6th-side machining, dimensional inspection of blanks, deburring, cleaning and much more. This ensures that every precision CNC machining part is produced with outstanding consistency and reliability.

Loading and unloading with multiple loading options

To meet the specific requirements of precision CNC machining parts, we offer multiple loading solutions:

- Standard: DIN palette system

- Options

- Stacking magazine (palette cart)

- Belt conveyor

- Robot

- Vibratory convey

- Manual loading

With this flexibility, the module adapts to different production environments, making it the perfect solution for companies requiring high precision machining parts and scalable automation.

Super-efficient machining modules

Each machining module is equipped with 2 working spindles that can be used alternatively. While one spindle is machining, the other is changing the cutting tool.

This setup ensures continuous high-precision machining, even for demanding precision machining parts, with zero downtime.

Overview of a working module

- 2x tool magazine discs with 18 tool slots, up to 36 tools per module.

- When stacked to the maximum level (4 modules), the Multistep XT-200 machining center can accommodate 144 tools

- 2x alternating spindles, chip-to-chip time less than 1 second at full spindle speed

- B/C-axis

- 5-axis transformation

- 260-degree B-axis rotation

- Liquid-cooled motors for B and C axes

- Free-rotating C-axis with a maximum speed of 600 rpm