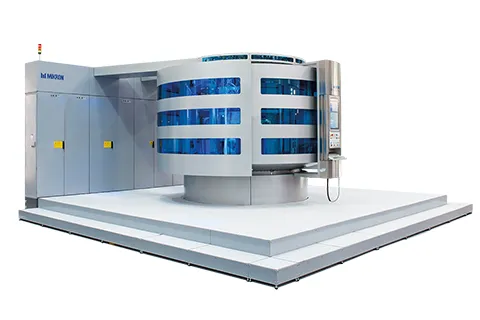

Highly Productive Machining

Companies in the automotive, electric, and electronic industries - as well as many other manufacturing sectors - demand high-volume production machining solutions that maximize efficiency and precision.

To stay competitive, manufacturers require high-volume mechanical or CNC machining systems capable of producing precisely machined, durable, and accurately fitting workpieces.

For over 115 years, Mikron Machining has continuously optimized the accuracy, quality, and productivity of its machines.

The result: highly productive machining solutions that enable manufacturers to produce precision parts in the micrometer range at exceptionally high speeds.

Comprehensive High Volume Production Machining

Mikron’s machining systems integrate multiple manufacturing processes - including turning, milling, drilling, reaming, deburring, and forming - into a highly efficient and synchronized workflow.

Key Productivity Features

- Multiple machining in a single clamping

- Up to 3 machining units per station

- Up to 24 working stations

- Up to 44 working units machining simultaneously

- Single or multiple cycle production (up to 600 parts/minute)